Products

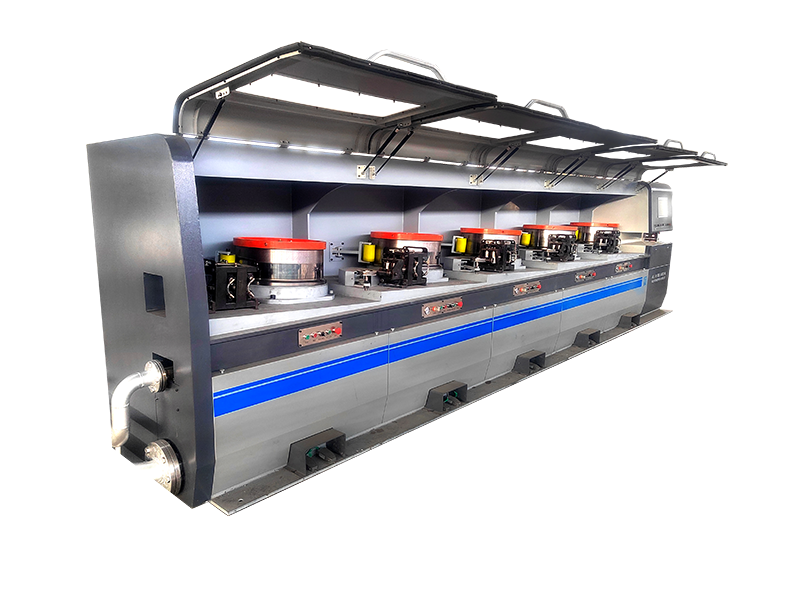

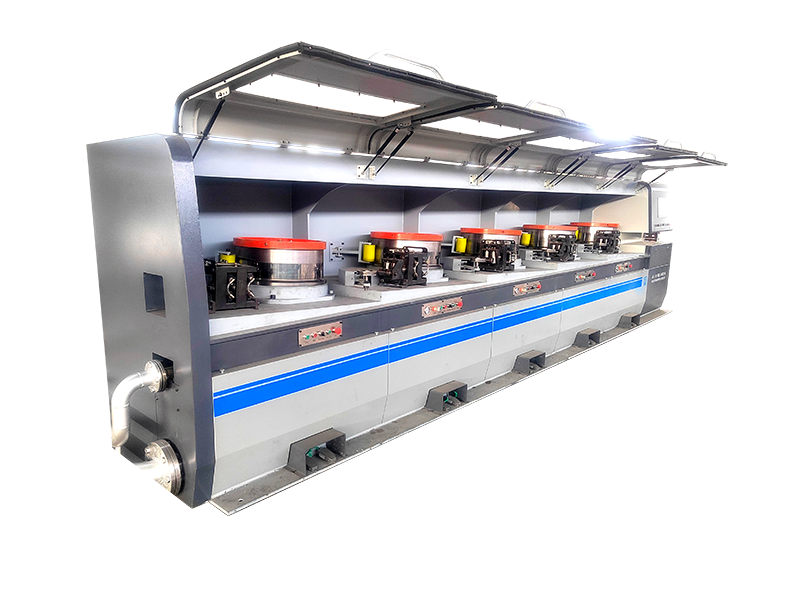

Titanium Wire Roller Die Drawing Machine – Contributing More Chinese Solutions To The Improvement Of The Titanium Industry

The new roller-die continuous straight-feed wire drawing machine is mainly designed for titanium wire drawing. It has excellent performance in cold drawing of pure titanium wire and various titanium alloy wires. When the equipment is used on the ground, the drawing speed is compared with traditional equipment. The drawing speed is increased by 5-10 times! According to the different production processes of customers, the wire drawing machine can also be matched with a richer range of pre-processing and post-processing online devices.

The wire drawing machine performs PID calculation through the cooperation of analog sensors and PLC to realize automatic speed adjustment between reels. The control system adopts Profinet communication protocol and network cable connection, which has very good high-speed stability and is also compatible with the entire workshop. IoT upgrade needs.

Many details such as the tuning arm of the wire drawing machine and the drum structure are tailor-made to meet the requirements of the roller mold.

The roller mold is made of high-quality tungsten carbide material and processed by high-precision machine tools. It has good drawing roundness and long service life. The roller mold structure has various combinations such as 2-piece, 4-piece, and 5-piece types, and the structure includes hot-drawn type and cold-drawn type. The roller mold is easy to maintain and use, and can replace imported roller molds.

The wire drawing machine has a variety of configurations and is customized according to the customer's on-site process::

| Drawn material | Reel diameter(mm) | Continuous pull times | Pulling speed

(M/min) |

Incoming wire diameter

(Mm) |

Outlet diameter(Mm) | Motor Power(Kw) | transfer method |

| Pure titanium wire, titanium alloy | Φ450~φ700 | 4~8 | 50~300 | Φ2.0~Φ8.0 | Φ6.5~Φ1.0 | 11~37 | Belt + reducer |