Products

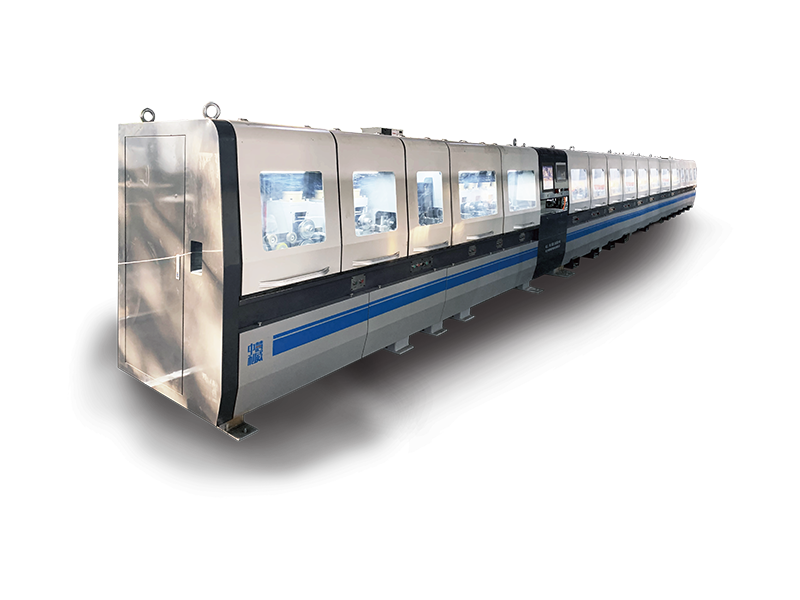

Flux Cored Wire All In One Machine

Since 2021, the new generation of flux-cored wire integrated machine independently developed by our company has been put into production and use by well-known domestic welding wire companies. The equipment adopts

A number of domestically pioneered advanced technologies improve efficiency, improve welding wire quality, and take a step towards production digitization.

The flux cored wire integrated machine completes the integrated production from steel strip, powder addition to finished welding wire. Take-up speed 30m/s, stand-alone production capacity 15 tons/day,

The floor space is 1.5 meters * 39 meters, saving 30% of the space. It eliminates the fine drawing process and reduces labor by 50%. The energy consumption per ton of welding wire produced is 130 kilowatt hours, which is higher than that of traditional welding wires.

The equipment is reduced by 40kwh/ton.

The flux-cored wire integrated machine is suitable for the production of different types of flux-cored welding wires such as carbon steel, stainless steel, and wear-resistant surfacing. Including all-in-one and split

All models have the advantages of high precision and high productivity.

| Function | Direct Drive Permanent Magnet ALL IN BOX:S4500-D |

Standard permanent magnet model ALL IN BOX:S4500-N |

Ordinary frequency converter split CX9+LZ6+LZ10 |

| Forming drive motor | servo motor | servo motor | Inverter motor |

| Wire drawing machine motor | Direct drive permanent magnet motor | Standard Permanent Magnet Motor | Inverter motor |

| Take-up machine motor | Standard Permanent Magnet Motor | Standard Permanent Magnet Motor | Inverter motor |

| transfer method | direct drive | belt drive | belt drive |

| Welding consumable type | carbon steel/stainless steel | carbon steel/stainless steel | carbon steel/stainless steel |

| total power | 204kw (excluding cleaning) | 198.5kw (excluding cleaning) | 236.25kw (excluding cleaning) |

| Take-up speed | 30m/s | 30m/s | 20m/s |

| Covered area | 1.3m(wide) *39m (long) | 1.5m(wide)*39m(long) | 1.5m(wide) *58m (long) |

| Reel diameter | ∅500mm | ∅500mm | ∅500mm+∅450mm |

| Built-in electric control cabinet | √ | √ | √ |

| Motor temperature detection | √ | √ | x |

| Wire drawing machine bearing temperature detection | √ | x | x |

| Motor grade one energy efficiency label | x | √ | x |

| Integral roller stand | √ | √ | √ |

| CNC roller lifting | √ | √ | x |

| Powder adding online weighing | √ | √ | x |

| Empty powder detection | √ | √ | √ |

| Roll mold | √ | √ | x |

| Roll mold automatic oiling system | √ | √ | x |

| The take-up machine and the pay-off machine automatically stop | √ | √ | x |

| Digitally controlled reversing of cable take-up and cable arrangement | √ | √ | √ |

| Full-time monitoring system | √ | √ | x |

| Appearance design of high-end machine tools | √ | √ | √ |

| Steel strip pre-treatment | high pressure water | high pressure water | x |

| Welding wire post-processing | scouring pad grater | scouring pad grater | scouring pad grater |

Product advantages

| Integrated roll stand | ||

| The machine base is integrated, and all the bars are in the same position before and after. The integrated frame must be manufactured with a gantry machining center in order to accurately loosen a screw and adjust the rod back and forth | ||

| Roller up and down adjustment | ||

| The machine tool feed system is used to control the lifting of the rolling stick, the electronic handwheel is operated, and the display screen is digitally displayed | ||

| Full-time monitoring | ||

| Observe the running status of the whole line at the position of the molding machine, and the Windows system touch screen is easy to operate and can be played back to trace the source of the problem | ||

| High-precision energy-saving motor | ||

| Forming machine roller: servo motor + planetary reducer Wire drawing machine, wire take-up machine: permanent magnet synchronous motor Wire organizer, powder adder: servo motor | ||

| High quality roller mold | ||

| Automatic lubrication, unit PLC control, high-quality YGB carbide material, long life, high precision, no running numbers | ||

| More advanced cable organizer | ||

| The servo motor operates the linear module cable arrangement. The reversal position is digitally displayed and set on the touch screen of the take-up machine. The reversal switch can be used to reverse the direction at will. | ||