Products

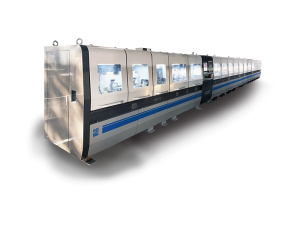

Core Welding Silk Rush Machine

The welded wire drawing process is completed by welding wires from thick to thinner, divided into rough pull units and elite units, and the rough units are used with the formation machine. The welding silk rush machine uses a straight turning wire,

The main components include: setting machine, long -headed handle machine host, qualifying speed adjustment, wire closing machine, etc. According to different production processes, the silk ripples have various styles.

| parameter | Pills core welding wire stretch units | Core welding wire essence unit |

| Reel diameter | ∅560mm | ∅450mm |

| Pulling passes | 6head~7head | 10head~11head |

| Incoming wire diameter | ∅2.8mm~∅5.0mm | ∅2.0mm~∅2.5mm |

| Outlet diameter | ∅1.8mm~∅2.5mm | ∅0.8mm~∅1.2mm |

| Motor Power | 11kw | 11kw |

| transfer method | Reducer + combined belt | Reducer + combined belt |

| other | Automatic die matching technology, no need to manually enter the mold diameter after replacing the wire drawing mold, the system will automatically identify, Adjust the speed between the rolls, automatic compensation after mold wear, not easy to break the wire. |

|

Write your message here and send it to us